It was 8°F outside, and Mrs. Patterson’s furnace in Worcester just gave up. Twenty years of faithful service, then nothing but cold air. By evening, she was writing a check for emergency replacement – paid through the nose because every HVAC guy in town was swamped.

Funny thing is, her brother Jim (who referred his sister to us at Endless Energy) saw this coming a year before. His furnace was making those same noises, same age as hers. He called us in August, planned everything out, got his new system installed in October for three grand less than what she paid. Sometimes the difference between smart and expensive is just timing.

Every year we keep seeing the same pattern. Homeowners ignore the warning signs until winter hits, then scramble for solutions. The smart ones? They’re already planning their next move while their current system still limps along.

Here’s what planning your HVAC replacement timeline actually looks like in Massachusetts.

Table of Contents

ToggleWhen to Start Planning (Hint: Earlier Than You Think)

Look, most folks around Worcester wait way too long. Come December they’re noticing their furnace struggles. February rolls around and they’re shopping. Problem is, so is everybody else whose heat just died.

You want to start thinking replacement when your system hits the teenage years – 12, 13, 14 years old. Not when it’s already on life support.

That old furnace isn’t getting younger. The heat pump making weird sounds? Won’t fix itself over summer break. These machines tell you when they’re tired – you just have to listen.

Here’s what I tell customers when they ask about warning signs:

Your heating bills jumping 25% year over year? That’s your system working harder to do the same job. Rooms that used to stay comfortable now run cold or hot? Internal components wearing out. Repair calls becoming a monthly thing? Time to cut your losses.

Endless Energy had a customer in Framingham whose furnace needed three service calls in one winter. Spent $2,100 on repairs for a 16-year-old system. Could’ve put that money toward replacement and been ahead of the game.

The Best Times to Replace HVAC in Massachusetts

April and May? That’s the golden window.

Weather’s perfect, we’re not crazy busy yet, and you’ve got time to do this right. No rushing, no emergency pricing, no settling for whatever equipment happens to be sitting on the shelf.

This past spring Endless Energy replaced a whole system for a customer in Waltham. He’d been planning since the previous fall when his old boiler started acting up. Got Mass Save rebates processed smooth as silk, saved himself 2,800 bucks compared to what emergency work would’ve cost. Two comfortable days of installation, system tested and running perfect before any real cold hit.

September, October – still decent timing

Missed the spring window? Fall’s your second choice. Weather cooperates, you can test your heating before the real cold hits. Just know that contractors get busier once October rolls around, so don’t wait until Halloween to make your calls. Remember: the first morning with frost on the ground marks the start of the HVAC heating season!

Summer replacement

Only makes sense if your AC died or you’re adding cooling. Around here, summers aren’t brutal like down south, but nobody wants to sweat through July without air conditioning.

Emergency Winter Replacement: What It Really Costs

Winter installation is expensive and miserable for everyone involved.

Emergency calls cost you 15, maybe 20 percent more than planned work. That 12-grand spring job becomes 14 or 15 grand in January. Distributors run low on the good stuff, so you might end up with whatever’s available instead of what actually fits your house best.

And when it’s 15 degrees and your heat’s not working, you can’t exactly take your time researching contractors or shopping around for quotes.

Remember that brutal cold snap two Februaries back? Customer in Concord had his oil furnace die right in the middle of it. Emergency replacement ran him $16,500 for work that would’ve cost $13,200 in April. Plus he shelled out 400 bucks keeping the house warm with space heaters during the three-day install. Expensive lesson in bad timing.

How This Actually Works Out

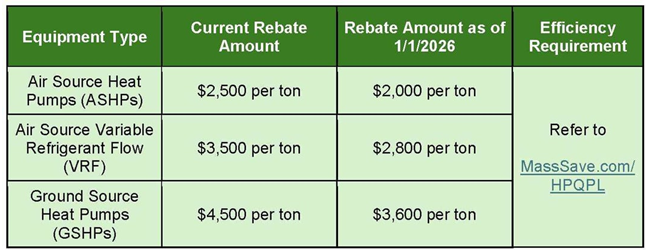

A year before you need it done: Start noticing how your system performs. Track those heating bills. Look into Mass Save rebates – might as well understand what money’s available.

Six months out: Time to get serious. Call three, four contractors. Get them to actually calculate what size system you need instead of just eyeballing it. Research equipment options. Start the Mass Save paperwork if you qualify.

Three months ahead: Make your decisions. Pick your contractor and equipment. Lock in installation timing. Handle financing and any electrical work that needs doing.

Month before installation: Confirm everything twice. Clear out the basement or wherever they’ll be working. Take time off work – you want to be around when they’re installing a 15-grand system.

Installation week: Be available for questions. Test everything thoroughly. Get your maintenance scheduled.

Massachusetts-Specific Timing Considerations

Mass Save Program Timing Rebate funds sometimes run out by year-end. We’ve seen customers lose $2,000+ in rebates because they waited until November to start their process and couldn’t get installed until the next year (and the rebate rules changed). Start the rebate process 4-6 months before installation.

Permit and Inspection Schedules Worcester building department gets backed up in fall as contractors rush to beat winter. Newton and Framingham have similar delays. Plan permit applications weeks before installation.

Weather Windows Massachusetts weather can be unpredictable. Plan installation for periods with 3-4 day clear forecasts.

Contractor Seasonal Demand Our busiest months: October-December (heating prep) and June-July (AC emergencies). Plan around these periods for better availability and pricing.

Stuff That’ll Slow You Down

Electrical work Half the houses built before 1980 need electrical upgrades for new heat pumps. Add a couple weeks to coordinate with electricians. Fortunately we make this easy at Endless Energy with in-house electricians!

Permits and inspections Worcester building department gets backed up in fall when everyone’s rushing to beat winter. Newton, Framingham – same story. Start permit applications two months early.

Equipment availability

High-efficiency equipment sometimes has longer wait times. Popular Mitsubishi models might need a month or more during busy season.

Ductwork surprises That old ductwork in your 1960s Reading colonial might need more work than expected. Duct cleaning, sealing, replacement – adds time (and money) to every job.

How to Compress Your Timeline (When Necessary)

Sometimes life doesn’t cooperate with perfect timing. Your system dies in November, or you buy a house with ancient equipment. Here’s how to speed things up without completely screwing yourself:

Get financing and rebate paperwork started before you even pick your contractor. Choose equipment that’s actually in stock instead of special-order stuff. Be flexible on scheduling – available when the contractor has an opening. Prep the work area ahead of time.

Had a customer in Milton buy a house in September with a dying boiler. We compressed what usually takes two months into three weeks. Used in-stock equipment, had electrical work running parallel, grabbed the first good installation window. Not perfect timing, but way better than emergency winter replacement.

Bad timing costs real money. Emergency work runs 15-25% higher. You get stuck with whatever equipment’s available. Rush decisions mean higher chance of regrets later. Less time to shop financing or arrange Mass Save loans. Weather delays, installation problems, everything’s compressed and stressful.

Good timing saves money. Spring installations often 20 percent less expensive. Better equipment choices, better contractor availability. Time to properly size everything and plan the work right. Maximum rebate opportunities. Comfortable conditions for installation.

Whether you’re in a Worcester triple-decker, Framingham colonial, or one of those big Newtons, your replacement timeline should match your situation. Planning replacement with a 10-year-old system? Start thinking 6-12 months out, install in spring. System already failing with frequent repairs? Start now, try to limp through the season, replace in off-season. Emergency replacement because everything just died? Move fast but don’t panic – still get multiple quotes even when you’re desperate.

Bottom line: every month you wait costs money. Emergency pricing, missed rebates, or settling for whatever’s available instead of what you actually want.

Want to start planning your replacement the right way? Call us. We’ll look at your current system, talk through timing options, help you create a timeline that saves money and avoids stress. Been doing this since 1980 – we know what works.

Call today or visit our website. Don’t wait until your system dies to start planning.