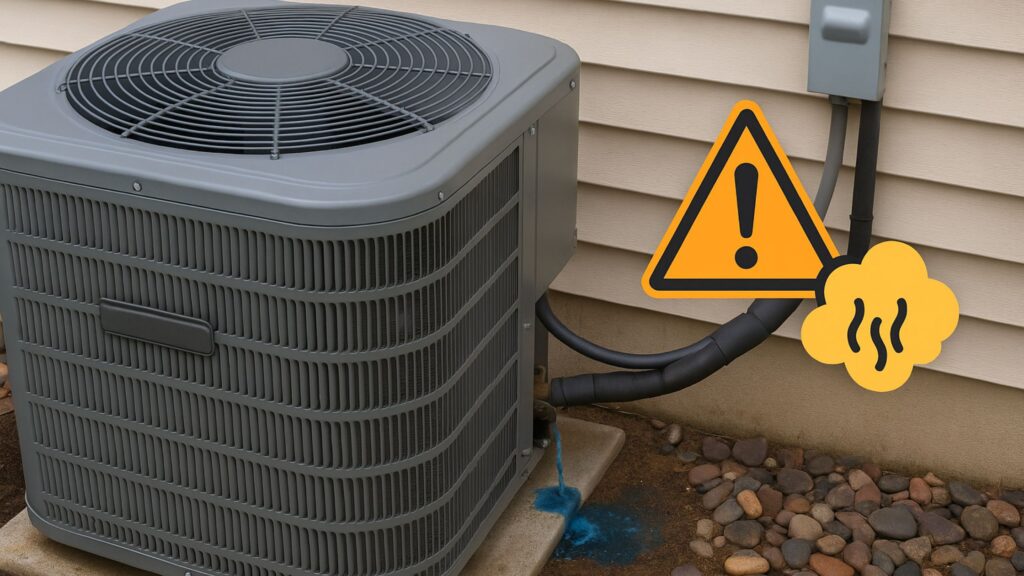

An AC refrigerant leak can quietly undermine a homeowner’s comfort and drive up energy bills without warning. When the cooling agent—often called Freon or refrigerant—escapes the closed circuit of an air conditioning system, efficiency plummets and potential hazards arise. Early detection of an AC refrigerant leak is crucial for preventing system damage and mitigating health and environmental risks. Throughout this guide, readers will learn the telltale warning signs, understand why leaks occur, and discover best practices for safe, professional repairs.

Table of Contents

ToggleHow can you tell if your AC is leaking refrigerant?

An unmistakable symptom of an AC refrigerant leak is diminished cooling power. When refrigerant levels fall below optimal pressure, the system loses its ability to exchange heat effectively, causing indoor temperatures to climb despite constant fan operation. A technician may note that the evaporator coil freezes as the remaining coolant becomes too cold, turning condensation into ice and blocking airflow. In some cases, homeowners may also notice water pooling near the indoor unit, which can be related to issues discussed in Why Is Water Leaking From Indoor AC Unit.

Short cycling—where the air conditioner frequently turns on and off—can also signal low refrigerant levels. This erratic behavior occurs because the compressor struggles to maintain pressure, triggering built-in safety controls. Over time, repeated short cycling stresses electrical components and reduces the lifespan of the compressor.

Another clue lies in unusual sounds emanating from the unit. A hissing or bubbling noise often accompanies a refrigerant leak as the pressurized gas escapes through cracks or pinholes in copper tubing or at soldered joints. In severe cases, a gurgling or sloshing sound may indicate large volumes of escaping refrigerant and oil mixture.

Rising humidity indoors can accompany an AC refrigerant leak. Because refrigerant is responsible for removing moisture from circulating air, depleted levels fail to dehumidify properly, leaving residents uncomfortable and potentially risking mold growth. Monitoring indoor moisture is therefore as important as checking temperature differentials across vents.

Why does an AC refrigerant leak occur?

Corrosion of copper refrigerant lines and coils is one of the most common culprits behind leaks. In coastal or high-humidity environments, metal components degrade faster, developing micro-abrasions that allow refrigerant to seep out over time. Even minute corrosion spots can expand under pressure, intensifying the leak.

Manufacturer defects and improper installation also contribute to premature leaks. Faulty brazing, misaligned connections or over-tightened fittings introduce stress concentrations that eventually fracture. A thorough pre-installation inspection by a certified HVAC technician can catch many of these issues before the unit goes into service.

Normal wear and tear—vibration from compressor operation and temperature cycling—fatigues tubing walls and solder joints. Over several years, this mechanical motion loosens connections and creates hairline cracks. Regular maintenance visits, including leak detection tests, can identify fatigue-related faults before they worsen.

Accidental damage during home renovations or landscaping activities can puncture exposed refrigerant lines, leading to immediate and noticeable leaks. Technicians recommend routing refrigerant piping away from high-traffic zones and protecting outdoor units from lawnmower strikes or garden tools.

What are the health and environmental dangers of an AC refrigerant leak?

Exposure to airborne refrigerants, especially older R-22 (Freon), can trigger respiratory irritation, headaches and dizziness. While brief exposure in a well-ventilated area poses minimal risk, prolonged inhalation of high concentrations may lead to serious complications such as shortness of breath and central nervous system depression.

Children and pets face heightened vulnerability because certain refrigerants are heavier than air and settle near floor level. In a sealed room, lingering R-22 vapors can accumulate, increasing the risk of frostbite-like skin burns or chemical irritation upon direct contact. It’s imperative to vacate affected spaces and ensure proper ventilation at the first sign of a leak.

Older refrigerants like R-22 also contribute to ozone layer depletion, prompting global phase-out under the Montreal Protocol. Even more eco-friendly alternatives such as R-410A possess substantial global warming potential if released into the atmosphere. Proper containment and certified disposal are crucial to meet EPA regulations and minimize environmental harm.

Low refrigerant levels lead to compressor overheat and failure. When an AC system runs dry, the compressor lacks proper lubrication and temperature regulation, often resulting in total system breakdown. Emergency ac repair becomes inevitable, and in many cases, a full compressor replacement or complete system swap is more cost-effective than salvaging a severely damaged unit.

How do HVAC technicians detect and repair refrigerant leaks?

Certified technicians employ electronic leak detectors capable of sensing refrigerant molecules in concentrations as low as a few parts per million. These handheld devices scan coils, tubing and valve connections to pinpoint leak sources with high accuracy. Technicians may also use fluorescent dye injection during maintenance checkups to visualize leak paths under UV light.

Pressure testing the system with dry nitrogen helps isolate and locate leaks in hard-to-access sections. The technician pressurizes the closed loop, listens for escaping gas, and inspects the system for pressure drops on a calibrated gauge. This method safeguards the unit against contamination that could occur if oxygen or moisture enters the refrigerant lines.

Refrigerant line repair often involves cutting out and replacing corroded sections of copper tubing or re-brazing weakened joints. Technicians ensure a clean, flux-free surface before soldering, followed by vacuum dehydration to eliminate moisture. Finally, the system is recharged to manufacturer-specified refrigerant pressure, verified with precise digital gauges.

Table 1: Compares common leak detection methods:

| Leak Detection Method | Accuracy | Typical Use Case |

| Electronic Leak Detector | High | General inspection and pinpointing |

| UV Dye and Black Light | Medium | Locating hairline leaks in coils |

| Nitrogen Pressure Test | Very High | Verifying weld integrity and joints |

| Soap Bubble Test | Low to Medium | Quick field check of obvious leaks |

When should commercial vs. residential repair be scheduled?

Commercial ac repair demands faster turnaround times and stricter uptime requirements than residential ac repair. Businesses such as restaurants, retail locations and data centers rely on continuous cooling, so service contracts often include 24/7 emergency response and priority scheduling. Technicians work with commercial-grade refrigerant lines, larger condenser coils and complex control systems.

Residential homeowners typically book routine maintenance every spring and fall. A well-maintained residential unit can delay major repairs and avoid refrigerant loss. For urgent issues like a sudden refrigerant leak in the height of summer, many service providers offer same-day or next-day emergency ac repair to restore comfort and safety.

Regardless of setting, early detection of a refrigerant leak reduces repair scope and cost. A prompt air conditioning repair visit can salvage minor leaks in service valves or coil seams, preventing more invasive and costly interventions down the line. Preventive maintenance is an investment that pays dividends in energy savings and system longevity.

How much does it cost to repair an AC refrigerant leak in Massachusetts?

Repair costs vary widely based on the leak’s location, severity and refrigerant type. Below is a sample cost breakdown for common services in Massachusetts:

Table 2: Estimated Repair Costs in Massachusetts

| Service | Low-End Cost | High-End Cost |

| Leak Detection (Electronic/Nitrogen Test) | $100 | $300 |

| Minor Refrigerant Line Repair or Re-brazing | $200 | $600 |

| Compressor Overhaul After Leak Damage | $500 | $1,200 |

| System Recharge (R-410A) | $150 | $300 |

| Full System Replacement (R-22 to R-410A Swap) | $3,000 | $6,000 |

These estimates include labor and materials but exclude emergency service premiums. Homeowners seeking ac repair services in massachusetts are advised to request detailed quotes and compare service agreements before committing.

What steps should homeowners take after suspecting a leak?

Upon noticing any warning signs—hissing noises, ice buildup or warm air—homeowners should immediately turn off the AC system. Continuing to run a leaky unit can cause compressor burnout and circulate harmful gases indoors. It’s also wise to open windows and doors for ventilation and evacuate vulnerable occupants like children or pets until the area clears.

Documenting the symptoms and taking photos of ice-covered coils or stained refrigerant lines can aid the technician’s diagnosis. When discussing the issue, mentioning recent maintenance history and any odd sounds or smells helps narrow down potential leak sources. This preparation reduces on-site inspection time and accelerates repair.

Consumers can research local providers and schedule professional air conditioning service in massachusetts to confirm the leak and plan repairs. Many companies offer maintenance contracts that include annual leak detection, refrigerant checks and system tune-ups, helping prevent future disruptions and maintain warranty compliance.

How can regular maintenance prevent AC refrigerant leaks?

Seasonal inspections by HVAC professionals identify early signs of corrosion or fatigued fittings before they develop into active leaks. Technicians clean coils, change filters and verify refrigerant pressure to industry specifications, ensuring proper heat exchange and system balance. This proactive approach preserves refrigerant integrity and energy efficiency.

Routine vibration dampeners and pipe insulation replacements minimize mechanical stress on tubing runs. Addressing loose mounting brackets and worn-out grommets prevents the constant shaking that leads to micro-fractures. Proper insulation also avoids temperature fluctuations that cause condensation and subsequent corrosion.

Documented service reports track refrigerant levels over time, helping technicians spot gradual declines indicative of hidden leaks. Early detection through trend analysis allows swift, targeted repairs rather than full component replacements. It also aligns with EPA regulations requiring certified technicians for refrigerant handling and disposal.

Conclusion

Identifying an AC refrigerant leak early can safeguard indoor comfort, protect health and minimize environmental impact. Watch for reduced cooling efficiency, unexpected noise, ice buildup on coils and unexplained spikes in electricity bills. Certified HVAC technicians use advanced leak detection tools and precise repair methods to restore system integrity and efficiency. Whether it’s routine residential maintenance or expedited emergency ac repair, professional service is key to preventing compressor damage and ensuring compliance with EPA guidelines. If any sign appears, contact a trusted provider like Endless Energy for prompt, reliable solutions to AC refrigerant leaks.

(FAQs) Frequently Asked Questions

- How do I check for an AC refrigerant leak myself?

A homeowner can inspect visible refrigerant lines for oil stains or frost accumulation on coils. However, reliable detection requires electronic leak detectors or pressure testing by a certified technician.

- Is it safe to run an AC unit with a refrigerant leak?

Running a system with low refrigerant risks compressor failure and may circulate harmful gases indoors. It’s best to shut off the unit and schedule professional repairs immediately.

- What happens if a refrigerant leak goes unfixed?

An unfixed leak leads to reduced cooling capacity, inflated energy bills, potential compressor burnout and environmental harm due to escaping refrigerant.

- How long does a refrigerant repair take?

Simple leak detection and line repair can take 1–3 hours. More extensive repairs involving compressor replacement or system recharges may require a full day.

- Can you top up the refrigerant without fixing the leak?

Adding refrigerant without addressing the leak is a temporary fix that violates EPA regulations. Proper repair requires locating and sealing the leak before recharging the system.